Sustainable Concrete: Building a Greener Future

October 28, 2024

By Fortunato Orlando, PE

NYC Climate Week, September 22 – 26, 2024 was filled with many events, seminars, presentations, and documentaries and brought together leaders from business, government, academia, and civil society to discuss and implement climate action. The goal is to reach carbon neutrality with a 50% reduction by 2030 and 100% neutrality by 2050.

I have been asked by many; “What can a structural engineer bring to the table to lower the carbon footprint?” Ah! The one-trillion-dollar question! Concrete has been a worldwide commodity since the ancient Roman Empire and a product of convenience that cannot be eliminated. Concrete in its plastic state can be shaped and formed in almost infinite ways and when hardened will provide shelter and use for everyday life.

Concrete is the backbone of modern infrastructure. Its adaptability, and long lifespan enable us to create structures that stand the test of time. Yet, as we innovate and push the boundaries of design, there’s also a growing recognition that concrete, particularly its production, significantly contributes to carbon emissions. A clear understanding of this impact allows us to explore more sustainable approaches that minimize carbon footprint.

Concrete’s Environmental Impact

Concrete production accounts for about 8% of global carbon emissions. The main reason for this lies in one of its key ingredients – cement. Converting limestone and other raw materials into cement causes about 3.4% of global CO2 emissions, and there is no way to prevent the generation of CO2 in this process. As an example, Portland Cement is produced by cooking limestone and other materials in kilns at more than 1400 degrees Fahrenheit. To run these kilns, the major source of energy is produced by burning fossil fuels. The 8% of carbon is almost split equally by the carbon produced by the burning of fossil fuels and the carbon released by the limestone. So, how can we reduce concrete’s carbon footprint, especially given the environmental impact of cement and other components?

Addressing the Dilemma

Despite concrete’s environmental drawbacks, its unparalleled strength, durability and versatility make it irreplaceable in construction. The question then becomes, if we can’t eliminate concrete, how do we make it greener?

Solutions for Greener Concrete

There are several ways to make concrete more environmentally friendly, including:

● Reducing or replacing traditional cement with alternative products without compromising quality or performance

● Using Type 1L cement, which has a lower carbon footprint and has been used successfully in Europe

● Opting for sustainable concrete

What is Sustainable Concrete?

Sustainable concrete is a type of concrete that is produced using environmentally friendly methods and materials to minimize its impact on the environment. It is designed to have a low environmental impact throughout its life cycle.

Sustainable concrete is more durable, requires less maintenance, and has a longer lifespan, which can lead to cost savings over time. Additionally, the environmental benefits of sustainable concrete can help reduce long-term costs associated with environmental impacts.

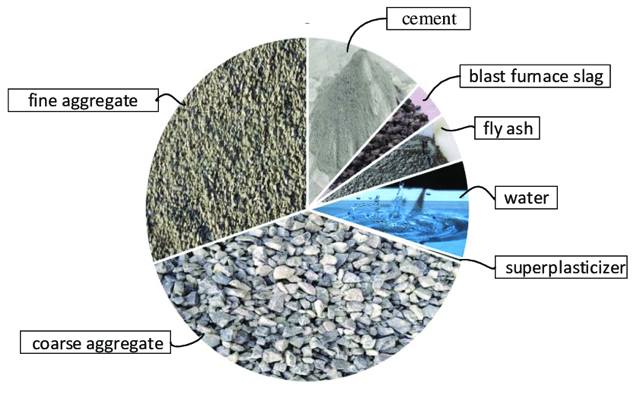

Components of Sustainable Concrete

Supplementary Cementitious Materials (SCMs)

By partially replacing cement with byproducts like fly ash, slag cement, and silica fume, we can reduce CO2 emissions while improving concrete properties such as workability and strength. SCMs help reduce waste from other industries but may slow down concrete’s setting time and strength development.

Recycled Aggregates

Recycled aggregates from construction and demolition waste can replace some natural aggregates. This reduces the need for virgin materials, diverts waste from landfills, and consumes less energy than processing new materials.

Admixtures

Eco-friendly admixtures enhance the sustainability of concrete by adjusting its properties. Water-reducing agents lower water content, reducing cement usage. Air-entraining agents improve freeze-thaw resistance, prolonging durability. Pozzolanic admixtures improve strength and reduce permeability, all while minimizing cement consumption.

Challenges in Adopting Sustainable Concrete

While sustainable concrete is the way forward, several challenges must be addressed.

1. The growing demand for greener materials could drive up costs or make them harder to source

2. Transportation of these materials could also add expenses and increase carbon emissions

3. Questions remain about whether these materials will be available in sufficient quantities at affordable prices

The Need for Collaboration

Achieving carbon-neutral concrete requires collaboration across the construction industry. Producers, contractors, designers, architects, engineers, and developers must work together toward a shared goal. Government bodies and local authorities should also update building codes and directives to support the use of sustainable alternatives in construction.

Promising Alternatives

Although we haven’t yet found a long-term solution to sustainable concrete, some innovative products show promise, such as:

● Sublime, which produces cement using a cleaner process

● GroundGlassPozzative®, a material that can replace traditional ingredients like slag and fly ash and reduce waste coming from thousands of miles away while also reducing the glass destined for landfills

● C-Crete, a cement-free concrete alternative

● Mimicrete, a concrete that heals itself for longer service life

Here at Severud, we have been pioneers in low-carbon concrete, controlling the amount of cement, and using high percentage of SCM’s like fly-ash, slag, micro silica, ground glass pozzolan [GGP]. The use of type 1L cement also helps to lower the carbon percentage. It has been largely used in Europe for the past half century and at higher percentages of limestone than that used in US.

As we advocate for sustainable practices, it’s crucial to remain open to new technologies and methods that can transform our construction approaches. A recent market study reveals that the global green building materials market is expected to expand from $474.21 billion in 2024 to $1,199.52 billion by 2032, reflecting a robust compound annual growth rate of 12.3%. This trend underscores the growing adoption of greener construction alternatives. Furthermore, implementing sustainable concrete practices has the potential to significantly reduce carbon emissions, thereby making a meaningful impact on the industry’s overall environmental footprint. Given that the construction sector accounts for 39% of global carbon emissions, every advancement toward more sustainable concrete represents a substantial stride forward.